Finding a formula for more sustainable chemicals use in cotton clothing

Tanya Cox and Rory Sullivan

From plastics to pesticides, textiles to toothpaste, the chemicals sector is critical to much of the global economy, with around 40-60,000 different chemicals used commercially.

But alongside the many everyday benefits and innovations that chemicals provide, are significant environmental and social risks ranging from water and soil pollution to human health & safety hazards, and data traceability issues. The sector is also responsible for significant greenhouse gas emissions - around 5% of total emissions according to one academic estimate.

To help manage these issues the UN led the development of the Global Framework for Chemicals (GFC), adopted in 2023. This is the world’s first comprehensive global framework to guide countries and stakeholders in addressing the lifecycle of chemicals, including products and waste.

As focus turns to implementation of the GFC, the Chronos team have been working with UNEP FI and other partners to analyse the use of chemicals in cotton used for apparel – a particularly significant sector - and to map financial flows work across its value chain.

Chemicals in cotton

Cotton is an enormous business. In 2023, over 24 million tonnes of cotton lint was produced with an estimated market value of $42 billion. And that requires an enormous about of chemicals.

Around 15,000 chemicals are used in the production of textiles – with an estimated 0.58 kg of chemicals used to produce just 1 kg of textiles. This makes textiles one of the highest chemical-dependent industries; and cotton fibre represents approximately a third of all raw materials used to produce clothing.

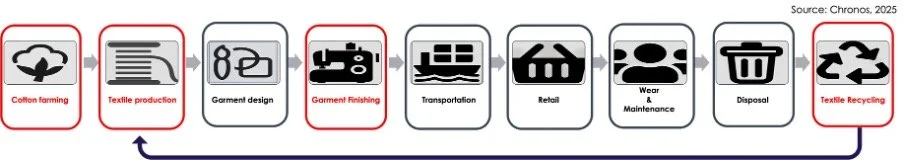

As part of our work to map chemicals use in the sector, we defined the cotton value chain as having nine key stages (See Figure 1). Across this value chain, we looked at the different types of chemicals used for different purposes such as performance, aesthetics and functionality. For example, we looked at the use of pesticides in cotton fibre production, dyes and colourants in preparation, and treatments for wrinkle resistance in finishing. We also looked at how emerging technologies for cotton recycling are also reliant on chemicals to breakdown cotton textile waste into pulp.

Figure 1: Nine stages of the cotton textile value chain.

We then identified the barriers to GFC implementation in each part of the cotton value chain, also highlighting levers for change. As a snapshot of these findings, some of the key challenges to align cotton value chains with GFC targets include:

Fragmented chemical policies on a global scale result in inconsistent elimination and phase out of the most harmful substances. Within this, weak regulatory and licencing frameworks mean harmful substances are readily available for use, at low costs.

High numbers of diverse stakeholders with low operating margins whose livelihoods rely on cotton production, sale and manufacturing.

Low transparency and traceability of the use – and fate – of chemicals across fragmented value chain.

Significant data gaps relating to the quantities and combinations of chemical substances used – particularly in post-fibre production stages of the life-cycle – and the monetary costs associated with social and environmental chemical impacts.

A material that is increasingly material

Another challenge, and one that is especially relevant to investors, is the absence of consolidated lists of harmful substances in use across different sectors and the absence of clear criteria or indicators for ‘GFC-aligned’ safer chemical alternatives. As the issue of unsustainable chemical use becomes increasingly recognised as a material risk to investors, there is a growing movement to develop indicators to form the basis for better disclose and close some of the data gaps.

We are seeing this movement in the form of recent investor statements, such as that facilitated by ShareAction, which reiterates that chemical pollution is at the nexus of climate action and biodiversity protection.

Uruguay and beyond

Last month, our CEO Dr. Rory Sullivan and Biodiversity & Nature Manager Tanya Cox were delighted to present some of the findings from our Chemicals sector work at the first UN-organised Open-Ended Working Group meeting of the Global Framework on Chemicals (GFC) in Punta del Este, Uruguay.

As part of the discussion we raised some of the indicative criteria that may need to be developed to help investors determine if investment decisions are GFC-compliant. For example:

Adopting EU ‘No data, no market’ rules which stipulate that manufacturers and importers of chemicals must identify and manage risks linked to substances produced or placed on the market would greatly increase transparency in chemical use and reduce risks across product life cycles.

Carefully designed, time-bound, multi-stakeholder Implementation Programmes for highly chemical-dependent sectors, like textiles, are vital to drive change in practices and fully support the implementation of the GFC targets and objectives.

In order to avoid regrettable substitutions, future chemicals policies must be science-led, precautionary and follow a hazard-based approach in line with the mitigation hierarchy.

Green and sustainable design and chemistry principles should be applied to promote system change in combination with the introduction of greener chemicals. And all solutions and technologies must be supported by full life cycle assessments that take into account wider social and environmental impacts.

Policymakers and regulators need to create an enabling environment that facilitates a just transition for all stakeholders and broad value-chain alignment with the GFC.

The next stage of our work involves (a) assessing the costs and benefits of the identified interventions, (b) identifying who could or should pay these costs, and (c) defining the role that could be played by the finance sector – investors, banks, insurers – and by other actors (e.g. customers, end consumers) financing these interventions. The overarching aim of this study is to develop a model for assessing financial flows with the need to align chemically-dependent sectors with the strategic targets and objectives of the GFC.

We look forward to working with all partners in the ongoing challenge of GFC implementation

--

If you’d like to get in touch with our team on GFC implementation, and the sustainability of the chemicals sector, please contact tanya.cox@chronossustainability.com

Photo by Kanishk Agarwal